|

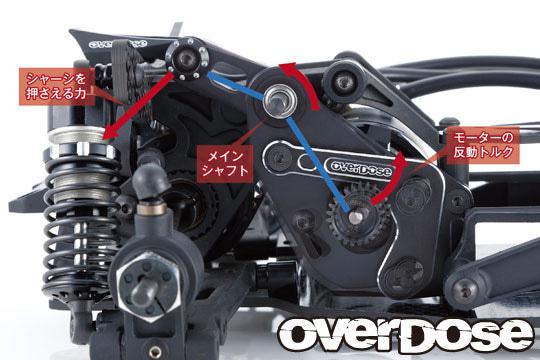

The floating motor mount system (F.M.M.S) converts the reaction torque of the motor from the bracket through the fulcrum and the working point to the pushing force of the rear end of rear bulk!

Due to the characteristic of the F.M.M.S, when directly to full throttle due to acceleration, the motor momentarily moves greatly due to reaction torque, but it soon comes off.

However, it doesn't move as much as you can see.

On the other hand, if a certain amount of torque is applied and kept at the throttle, the motor will remain in a state where force is applied.

This difference directly affects how the traction is applied.

When you full throttle at once, you get instant traction, and the throttle that keeps the torque applied is the image of continuous traction.

Therefore, F.M.M.S itself has a setting function so that you can control it to some extent! The working point.

The part that receives the movement of the motor running up the spur from the main shaft as a fulcrum and transmits it to the bracket.

Here is the setting element!

The collar enters the working point.

You can set the characteristics with hard rigid steel collar and O-ring.

The rigid collar applies force directly to the bracket, so you can get maximum traction!!

It is effective on carpet and asphalt roads.

The behavior change of rigid is smaller than that of O-ring.

It works more directly when used in gear drive.

The response is good.

The o-ring has a milder characteristic, so it is effective to control the load slowly on low-grip roads such as P-tile, colored concrete roads!

If it is a direct rigid, the effect will be reduced, so I recommend this one!!

In addition, the O-ring can be used in the general P3 standard, and it is possible to make more detailed settings depending on the hardness and number of O-rings.

|